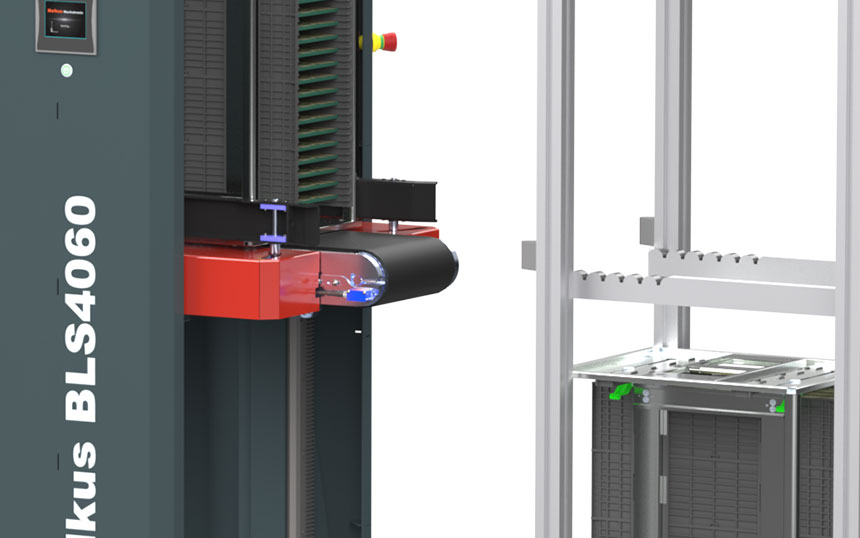

Optimised for PCB magazine and Euro-box transport, the dynamic small AGV Melkus Rack Stacker BLS4060 is tailored to the requirements of electronics or precision mechanics production. Thanks to its extremely compact design, it is used in production environments where space is at a premium and efficiently supports production processes.

Its innovative lift system enables it to flexibly transfer transport goods to transfer stations at different heights. Its integrated conveyor belt system facilitates precise and efficient transfers, ideal for seamless integration into production and assembly processes.

Technical Characteristics

Optimized for use

in very confined

spaces

in electronics

production

in precision mechanics manufacturing

for transporting small parts from A to B

for shelf

filling

Space-saving design

Optimized Transport

Flexible Handling

Efficiency & Safety

Intelligent Control

Maximum Efficiency for your Operations

Efficiency is the key to cost reduction. With its highly available AGVs, Melkus Mechatronic provides its customers with uninterrupted in-house transport with maximum flexibility.

Interested or have questions? Contact us – we’re happy to advise you!